CATEGORIES

FEATURED PRODUCTS

SHJ Series of Plastic modification Twin-screw extruder

Plastic Sheets Extruder PE PP PVC PBS PLA Sheets Machine Lines

WATER-RING PELLETIZING SYSTEM TWIN SCREW PLASTIC POE EXTRUDER

EVA Titanium powder added Photovoltaic PV membrane granules extruder large output capacity plasitc extruder

Recycling plastic regranulation extruder machine PE PP PET ABS recover granulation system recycling and reusing extruder

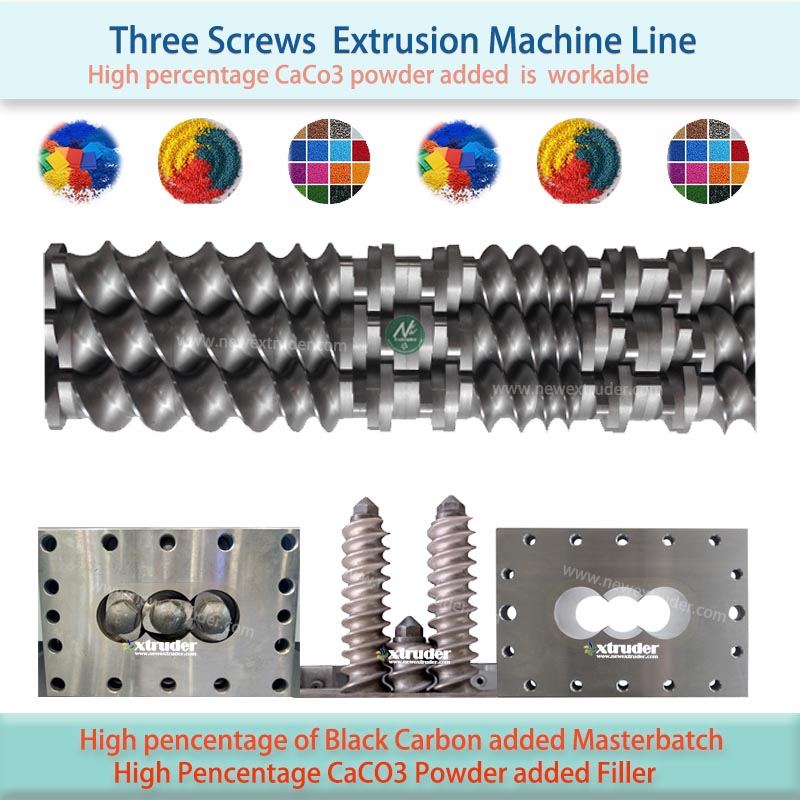

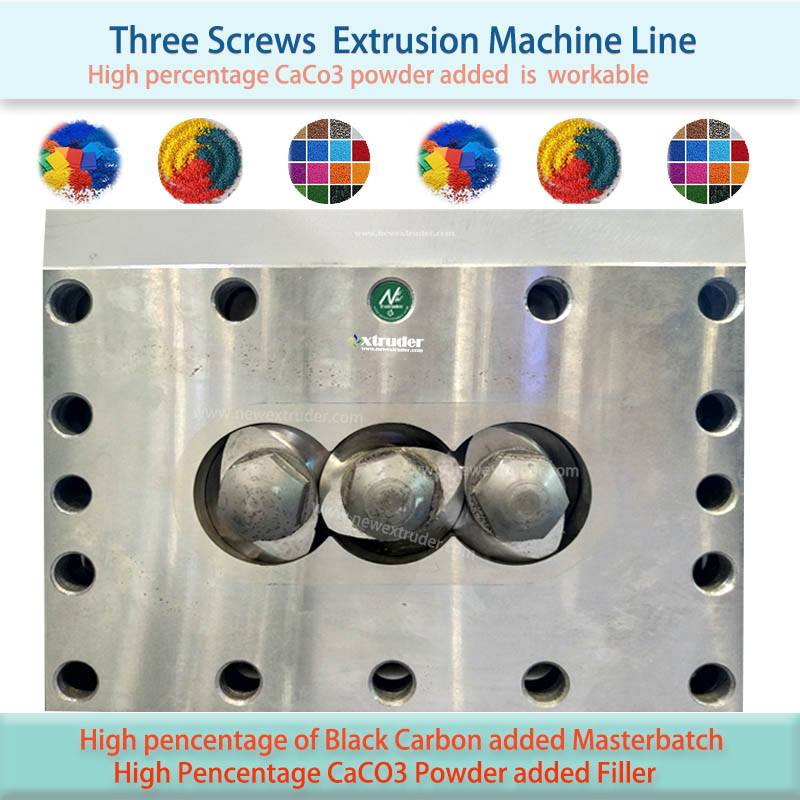

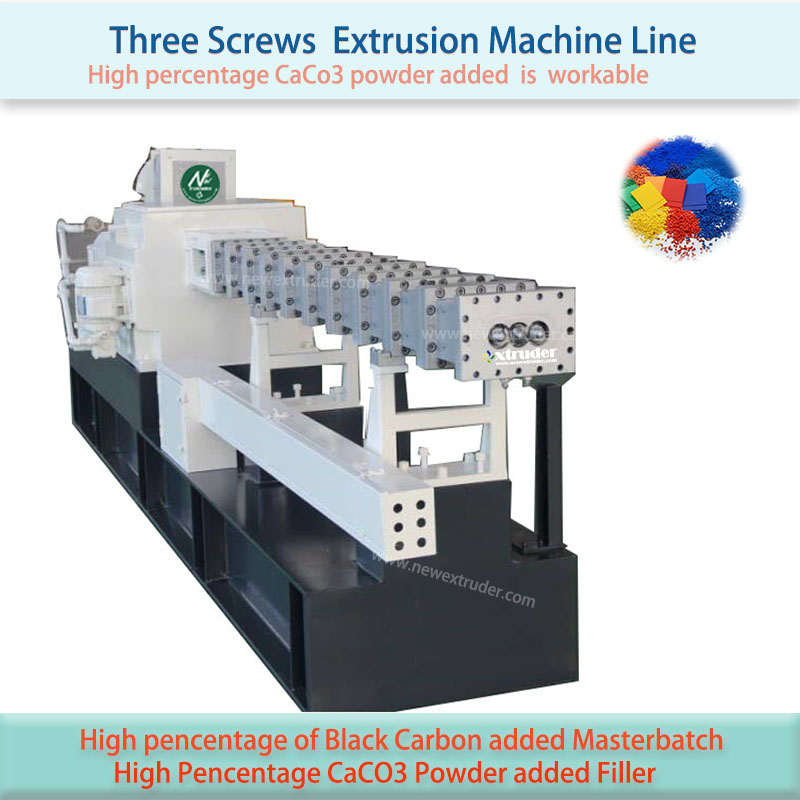

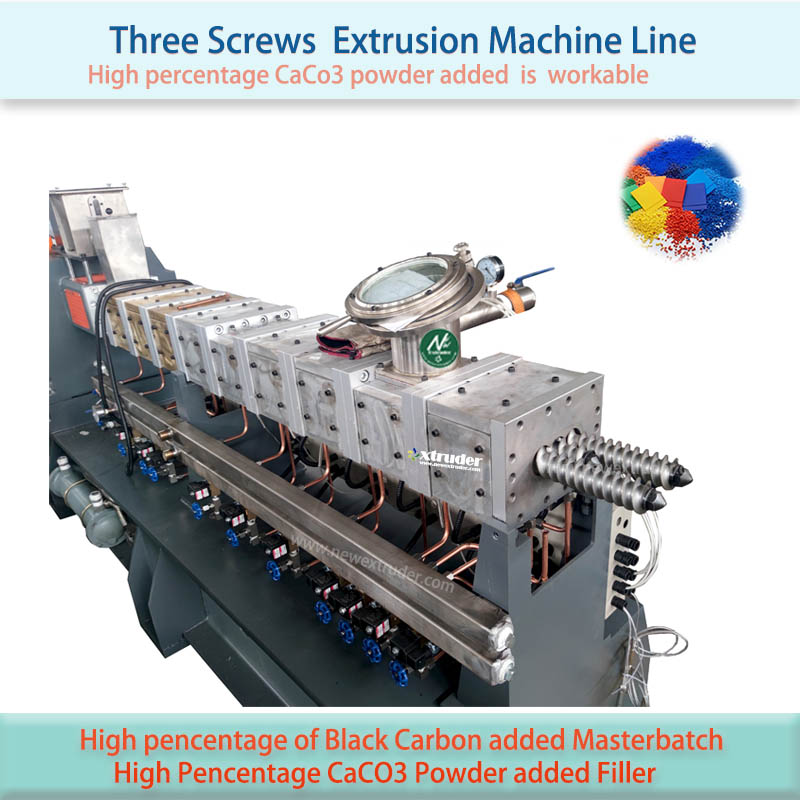

Three screw plastic extruder Triple screw Tri-screw extruder machine filler master batch extruder machine

SHORT DESCRIPTION:

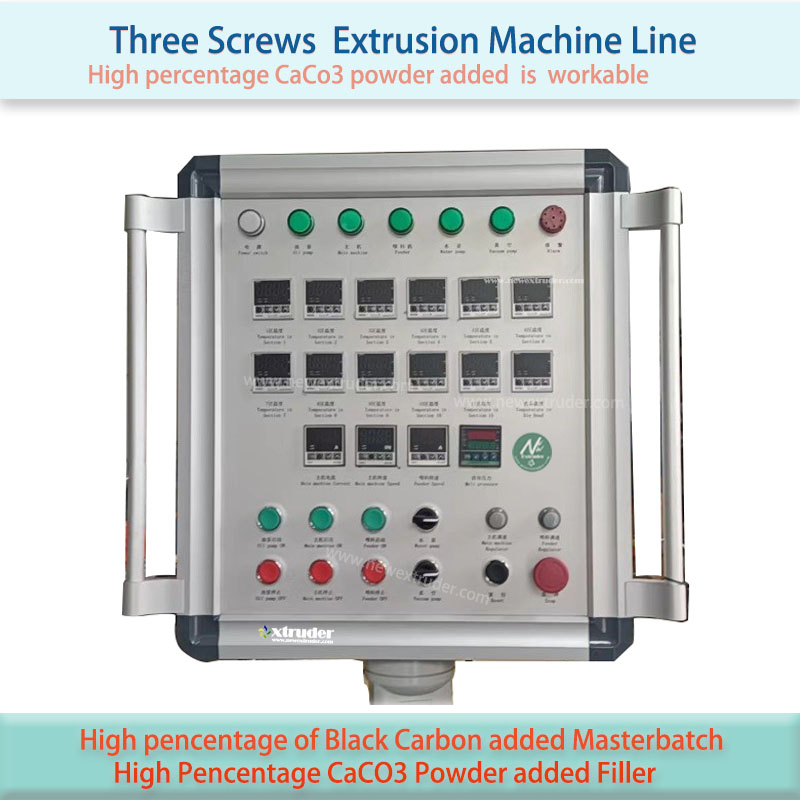

Application: This machine is designed for CaCO3 (Calcium Carbonate) powder (high percentage of this powder or BaSO4 powder) added filler masterbatch, which has High shear efficiency, good plasticizing effect, Good dispersion effect, short L/D ratio, High output capacity, and low energy consumption, Etc.

- Product Detail

- Our machine can process the following materials:

- Product Tags

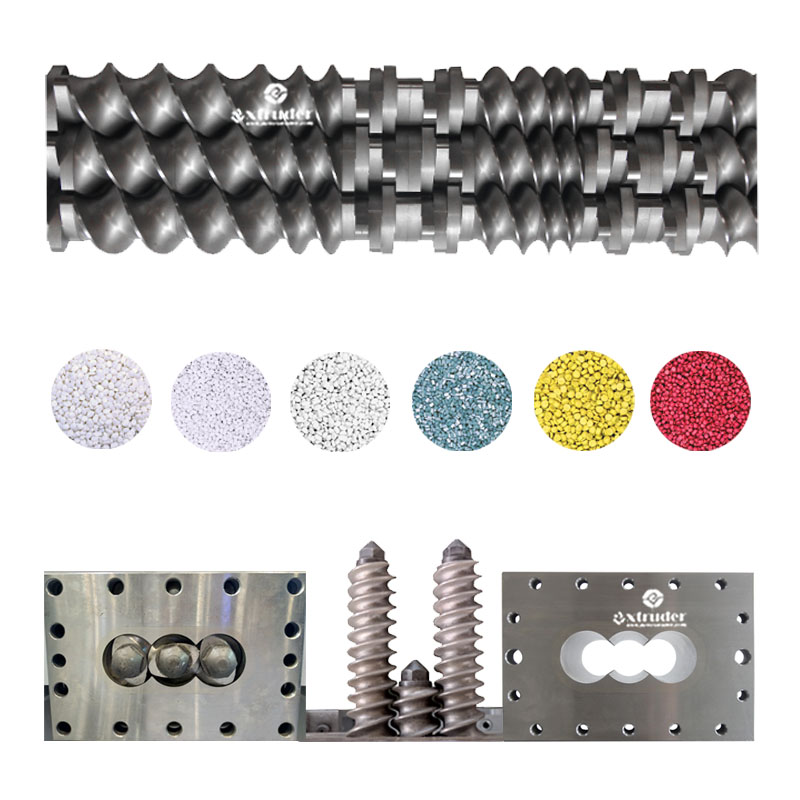

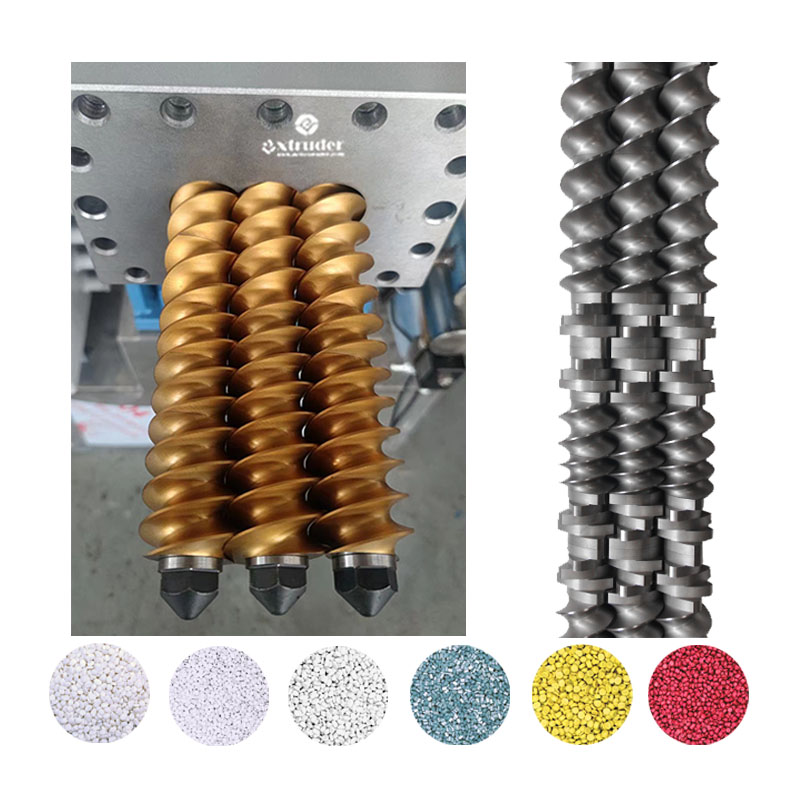

Triple screw plastic extruder Tri-screw extruder machine Three screw plastic extruder filler master batch extruder machine

HS CODE: 8477.2010

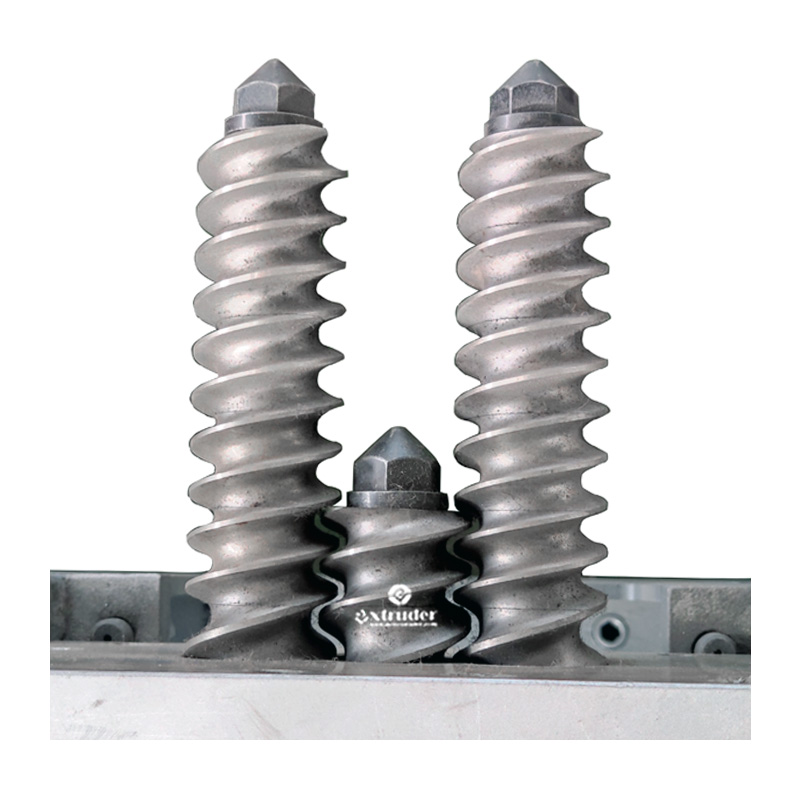

The comparison of the same type of parallel twin screw and parallel three screw in the color masterbatch and high filling plastic particles products making , the difference in equipment price is not big, but the difference in extrusion capacity is obvious, the three screw extrusion quantity is significantly higher than the parallel twin screw extrusion.

|

|

Advantages of parallel three screw extruder

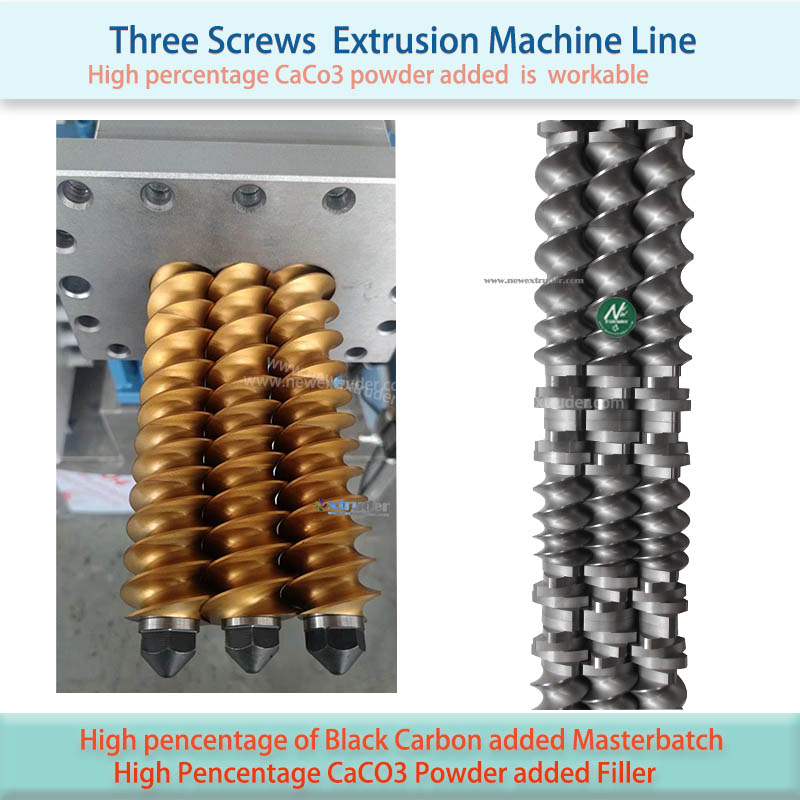

1. High shear efficiency, good plasticizing effect

In the in-phase parallel twin-screw extruder, there is only one meshing point between the root screws, and two meshing points between the three parallel screws in the same direction. Equivalent to 2 pairs of twin screw, because of high shear efficiency, plasticizing effect is higher than flat pair.

|

|

2. Good dispersion effect

Three screws are arranged in parallel, the volume between the screws of the cylinder is larger, the material flows in the cylinder is completed between the three screws, the flow is more disorderly, chaotic, the effect of intermolecular mixing is geometrically increased, so as to form a better dispersion, titanium blue, carbon black, high filling effect is obvious.

|

|

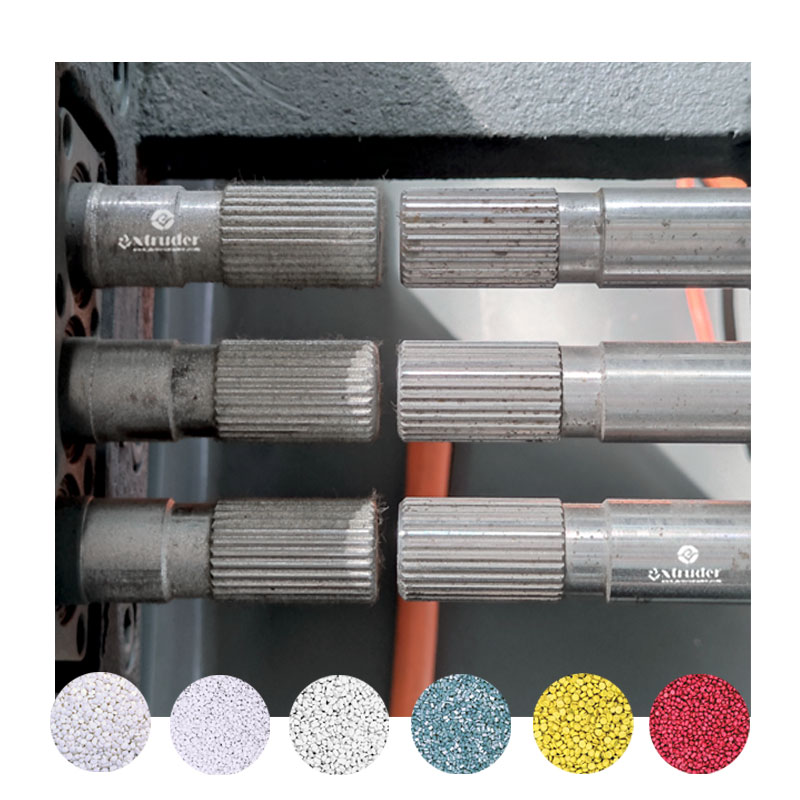

3. More short L/D ratio

The machine has two meshing points, equivalent to double the effect of Parallel twin screw extruder, can use lower length-diameter (L/D) ratio to complete the plasticizing mixing and dispersing work of higher length-diameter ratio of flat pair.

|

|

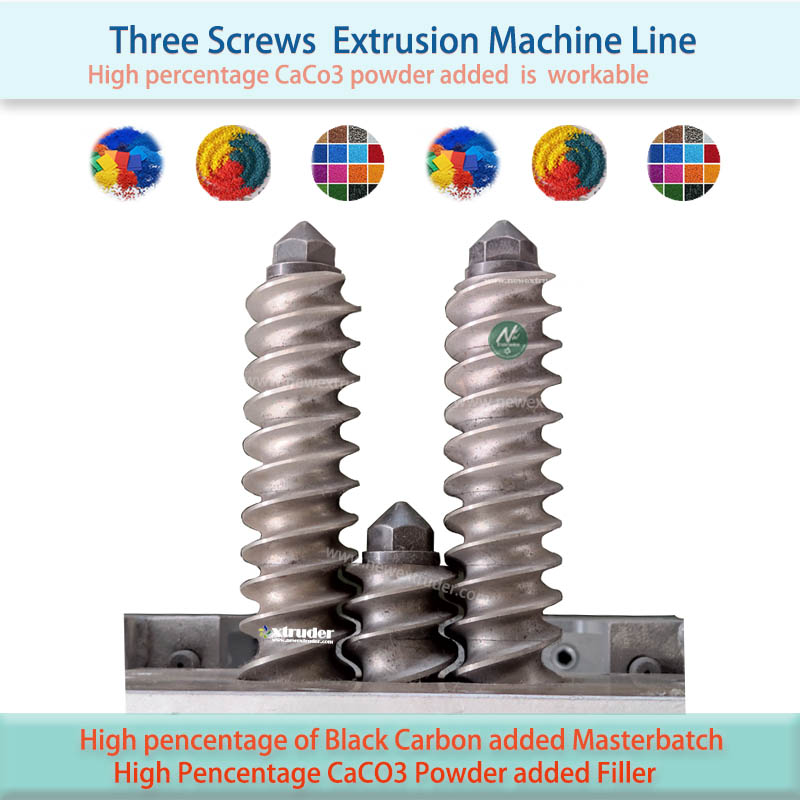

At the same time because of the length-diameter ratio is reduced, the material stays in the barrel for a shorter time, so it is more suitable for heat sensitive and afraid of degradation of the material.

On the other hand, due to the reduction of length-diameter ratio, the equipment occupies less installation space, which is convenient for equipment setting;

|

|

4. High output capacity and low energy consumption

Three screw output is the same specification, the same power twin screw extruder 1.5 times. For the production of the same number of products, the cost of manpower, site and so on is reduced exponentially. And because its length diameter ratio is short, the host power, heaters and other power decline and energy saving.

|

|

|

|

|

Process |

Representative materials |

|

Mixing nature-changing |

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA +Silicon rubber, etc. |

|

PE,PA,PC,CPE+ABS(alloy),PBT+PET,PP+ PE etc. |

|

|

Filling nature-changing |

PE,PP,EVA, etc.+ Calcium carbonate, talcum powder, titanic powder ABS,PC,PS, etc.+ aluminum hydroxide, magnesium hydroxide, antimony oxide. |

|

PP,PA,ABS +ferrous powder, sulphuric powder ceramic powder |

|

|

Functional machine pellets |

PP,PA,ABS,PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets |

|

PE,PP,PS, etc+ starch: de-composing machine pellets |

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets |

|

|

PE,EVA=ABS etc+ carbon black: black machine pellets |

|

|

Colored machine pellets |

PE,PP,ABS,AS,PA,EVA,PET +pigment and auxiliary |

|

Intensified glass fibers and carbon fibers |

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET etc.+ long fibers, small fibers, carbon fibers, crystals and so on, etc. |

|

Various cables |

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP, etc. insulating cables,coatings, PE peroxide silicon alkyl crossing cables: radialization crossing cables |

|

Special materials |

EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material |

|

Reaction extruding |

Poly-amide condensate, poly-amide melting polymerization, poly-amide polythene-adding, poly-carbonate condensate, etc. |

|

Exhausting and volatilization |

Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene |

|

Powder paint |

Polyester, ring oxide, lactide, polyurethane, acrylate |