FEATURED PRODUCTS

WHY CHOOSE KOSIN EXTRUDER

We have unique research in masterbatch and filling materials. Together with the Samsung Formula team in Korea, we have developed a new high-end color masterbatch and filler extruder machine, in the meatime, to help Koren client set up SUNNYTECH color masterbatch Production Company in Vietnam.

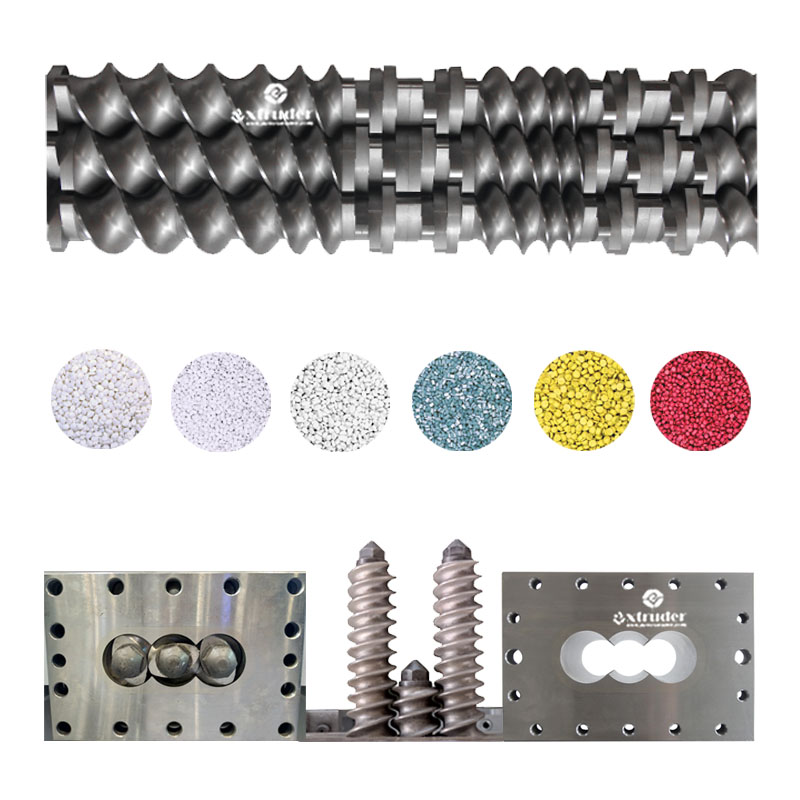

BETTER DISPERSION & DISTRIBUTION EFFECT OF COLOR MASTER AND HIGH CONCENTRATE FILLER

The design team updates the equipment and technology annually, improving the performance of the equipment by 20-30% and reducing the energy consumption by 10-15%; Thus saving user production costs and enhancing product competitiveness.

TECHNICAL SUPPORT & GOOD AFTER SALES SERVICE

Timely after-sales service! the service begins after the product sold, More than 10 after-sales service engineer team full-time service and professional consultation. Solve the problems in production in time. Customer comes first!

HOW TO CHOOSE A TWIN-SCREW EXTRUDER?

First of all, make sure the raw material you will use, such as PE, PP, PVC, or other types of plastic, second, choose the L/D ratio according to the customer's demand third, select the output capacity and determine the extruder machine mode for capacities, such as 50, 52, 58, 60, 65, 75, 95. 135 model, etc. for more question, please see FAQ page! Thanks!

CUSTOMER VISIT NEWS

ABOUT US

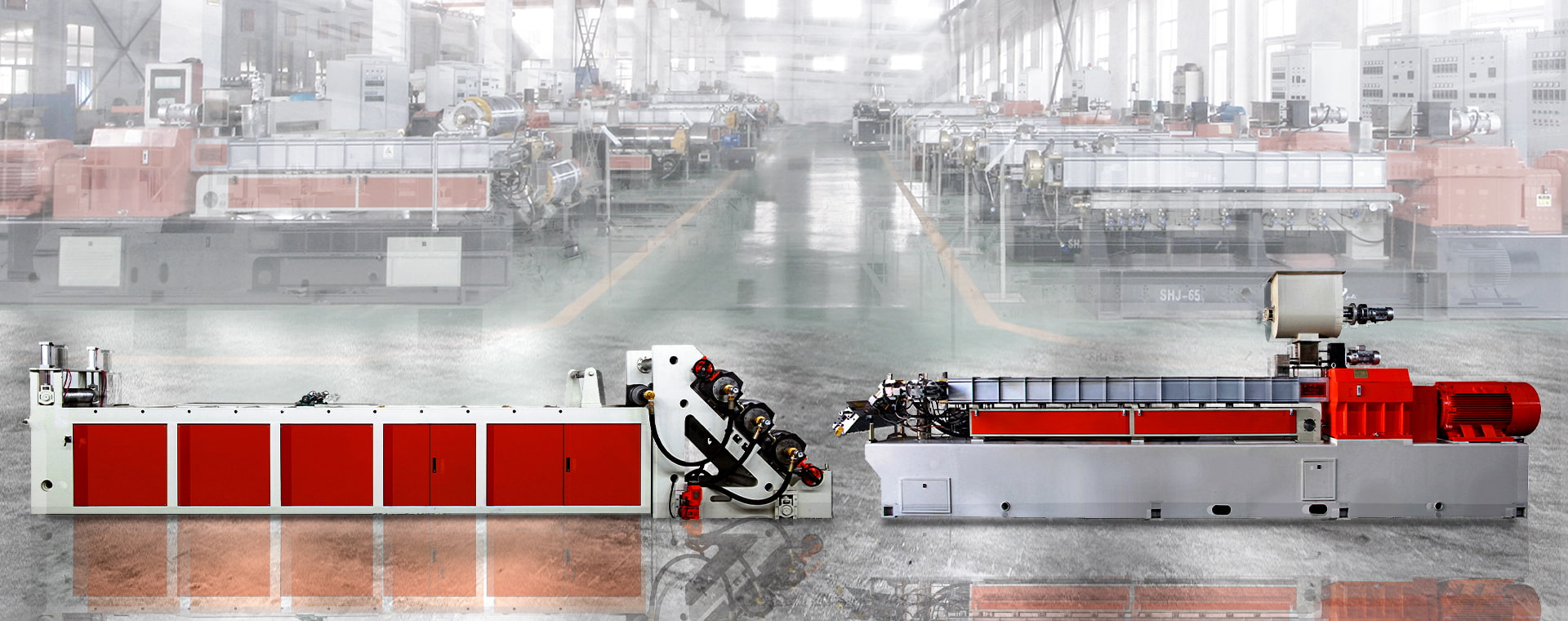

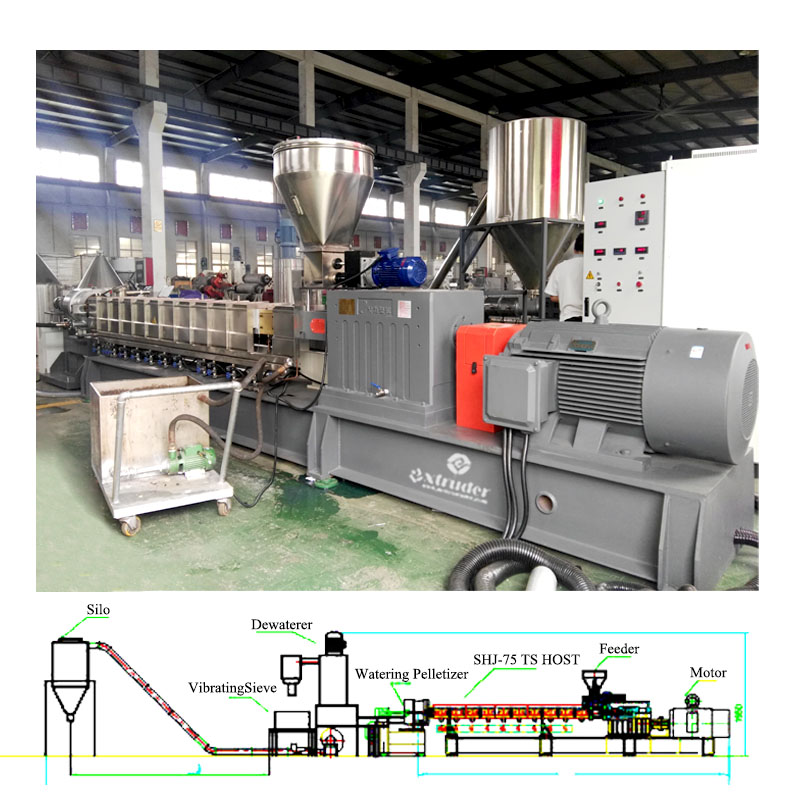

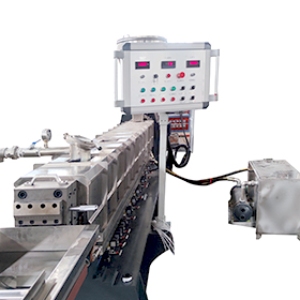

Kosin Extrusion Machinery Co., Ltd. is a specialized manufacturer of professional designing and making co-rotating parallel twin-screw extruders, three screws plastic extruders, bio-mass degradable plastic extruder granules and sheets extruder machine lines and its’ spare parts.

Our main products fall into reinforce and modification plastic business:

1) Co-rotating parallel method Twin screw plastic extrusion machine,

Biomass degradable plastic extruder, Three shafts(screws) plastic extruder Etc.:

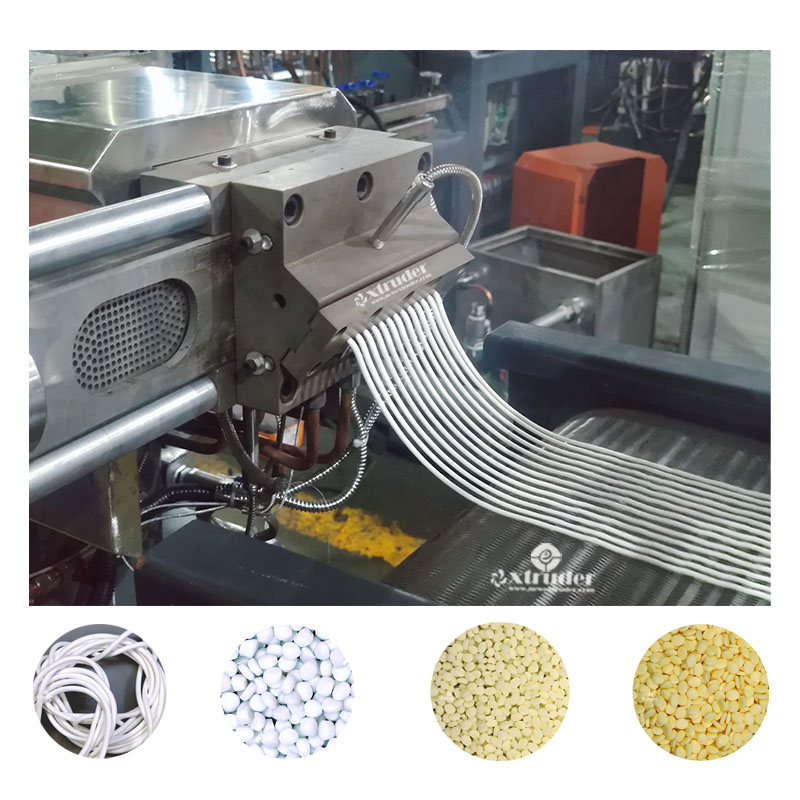

Various cutting methods, like to say:

*. Strand bathing water-cooled pelletizing system

*. Water ring cooled strand hot-face cutting system

*. Air-cooled strand hot-face cutting system

*. Air-cooled strand belt convoying pelletizing system;

*. Underwater pelletizing system;

2) Twin screw plastic sheet-making line; like to say PE/PP/PC/PET/PVC

3) for filler, color master batch, and recycling plastic particles’ large output capacity making.

4) Professional machine and equipment for the PCB business field. Our mission is: CUSTOMER COMES FIRST!