CATEGORIES

FEATURED PRODUCTS

SHJ Series of Plastic modification Twin-screw extruder

Plastic Sheets Extruder PE PP PVC PBS PLA Sheets Machine Lines

WATER-RING PELLETIZING SYSTEM TWIN SCREW PLASTIC POE EXTRUDER

EVA Titanium powder added Photovoltaic PV membrane granules extruder large output capacity plasitc extruder

Recycling plastic regranulation extruder machine PE PP PET ABS recover granulation system recycling and reusing extruder

TwinScrew Bio degradable PBAT PBS PLA Corn Starch plastic modification extruder machine SHJ75 plastic extruder

SHORT DESCRIPTION:

This machine could be used for BIO mass degradable plastic extruders like to say PBAT+PLA+Corn Starch powder or CaCO3 (Calcium Carbonate) powder for particle making;

- Product Detail

- Our machine can process the following materials:

- Product Tags

Bio degradable PBAT PBS PLA corn starch plastic twin screw extruder

HS CODE: 8477.2010

Usage:

This machine could be used for BIO mass degradable plastic extruder, like to say PBAT+PLA+Corn Starch powder or CaCO3 (Calcium Carbonate) powder for particles making;

PBS+PLA+ Starch powder or CaCO3 (Calcium Carbonate) powder for sheets making.

|

|

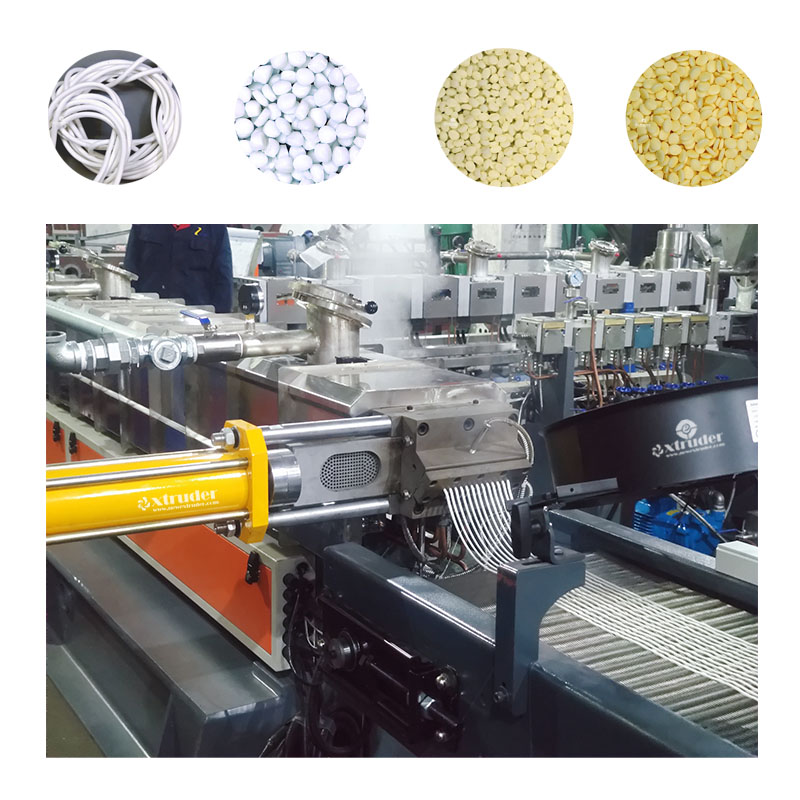

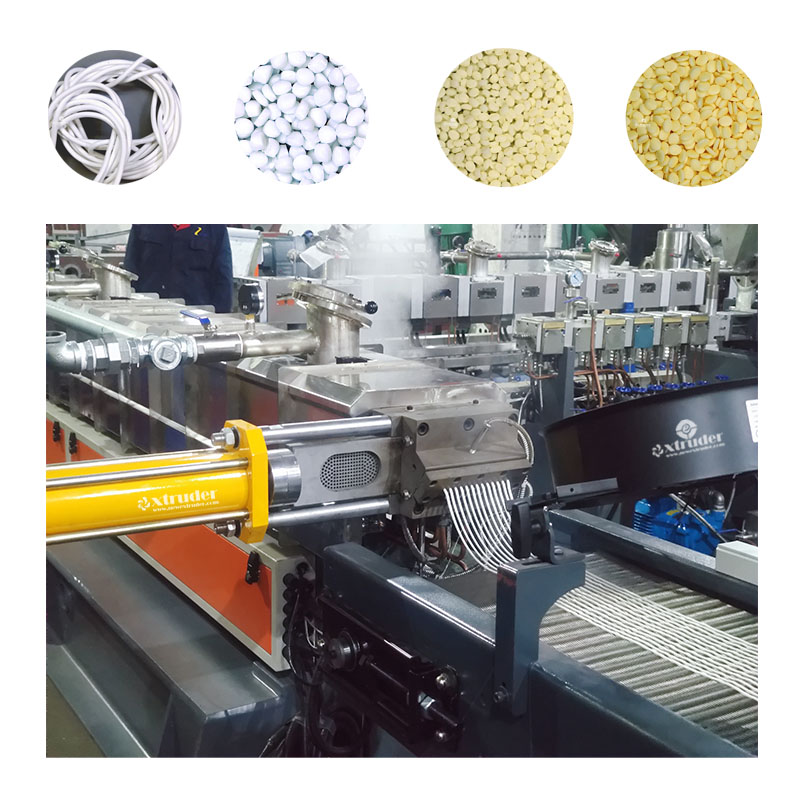

For this SHJ75 Twin screw plastic extruder, we have different kind of the mode:

SHJ-75A 110kw/L/D ratio: 40-60

SHJ-75B 132/160kw/L/D ratio: 40-60

SHJ-75D 220kw/L/D ratio: 40-60

SHJ-75G 250kw/L/D ratio: 40-60

The above SHJ75 Twinscrew plastic extruder could be produced the following granules:

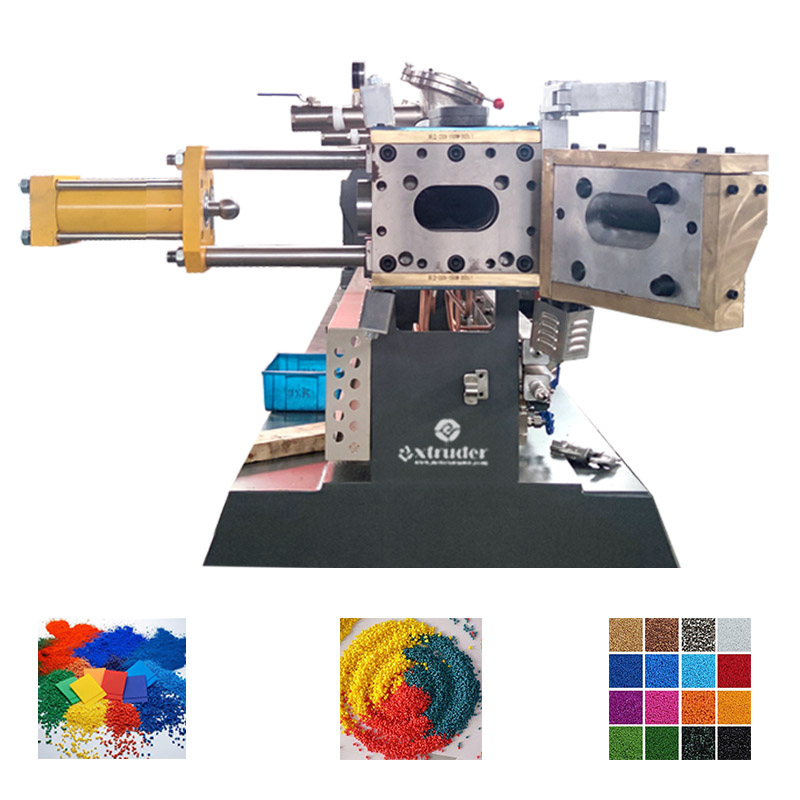

single color and large output capacity of color master batch making;

CaCO3 powder, BaSO4 powder, Titaninum powder, Talcium powder added Filler making;

Bio-degradable plastic modification particle making, like PBAT, PBS, PLA and PBAT+PLA+St. or PBS+PLA+CaCO3 powder and Etc..

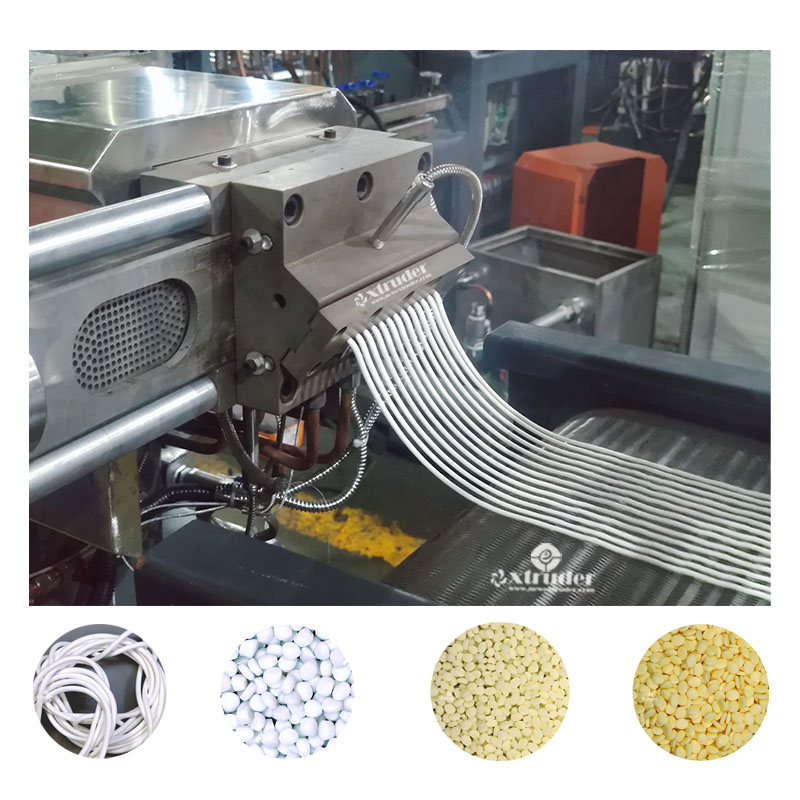

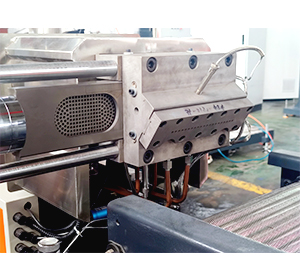

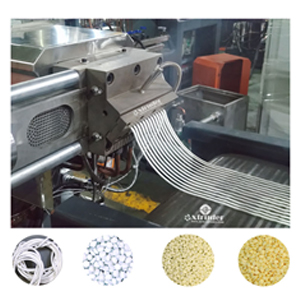

For cutting system, we have the following pelletizing method:

Strands bathing water cooled pelletizing system; (standard type)

Air cooling hot-face cutting system;

Water-ring cooled hot-face cutting system;

under water pelletizing system; (for elastomer and other special request of granules’ shape.)

Strands in water cutting system; (for easy broken material strands cutting)

Strands air cooling belt convoying system; (for bio degradable plastic modification particle, and high percentage of CaCO3 powder added strands.)

|

|

|

|

|

Process |

Representative materials |

|

Mixing nature-changing |

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA +Silicon rubber, etc. |

|

PE,PA,PC,CPE+ABS(alloy),PBT+PET,PP+ PE etc. |

|

|

Filling nature-changing |

PE,PP,EVA, etc.+ Calcium carbonate, talcum powder, titanic powder ABS,PC,PS, etc.+ aluminum hydroxide, magnesium hydroxide, antimony oxide. |

|

PP,PA,ABS +ferrous powder, sulphuric powder ceramic powder |

|

|

Functional machine pellets |

PP,PA,ABS,PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets |

|

PE,PP,PS, etc+ starch: de-composing machine pellets |

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets |

|

|

PE,EVA=ABS etc+ carbon black: black machine pellets |

|

|

Colored machine pellets |

PE,PP,ABS,AS,PA,EVA,PET +pigment and auxiliary |

|

Intensified glass fibers and carbon fibers |

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET etc.+ long fibers, small fibers, carbon fibers, crystals and so on, etc. |

|

Various cables |

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP, etc. insulating cables,coatings, PE peroxide silicon alkyl crossing cables: radialization crossing cables |

|

Special materials |

EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material |

|

Reaction extruding |

Poly-amide condensate, poly-amide melting polymerization, poly-amide polythene-adding, poly-carbonate condensate, etc. |

|

Exhausting and volatilization |

Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene |

|

Powder paint |

Polyester, ring oxide, lactide, polyurethane, acrylate |